| Index name | National Standard | STRONGER 232C |

|---|---|---|

| Colour | White/Gray/Light pink | White |

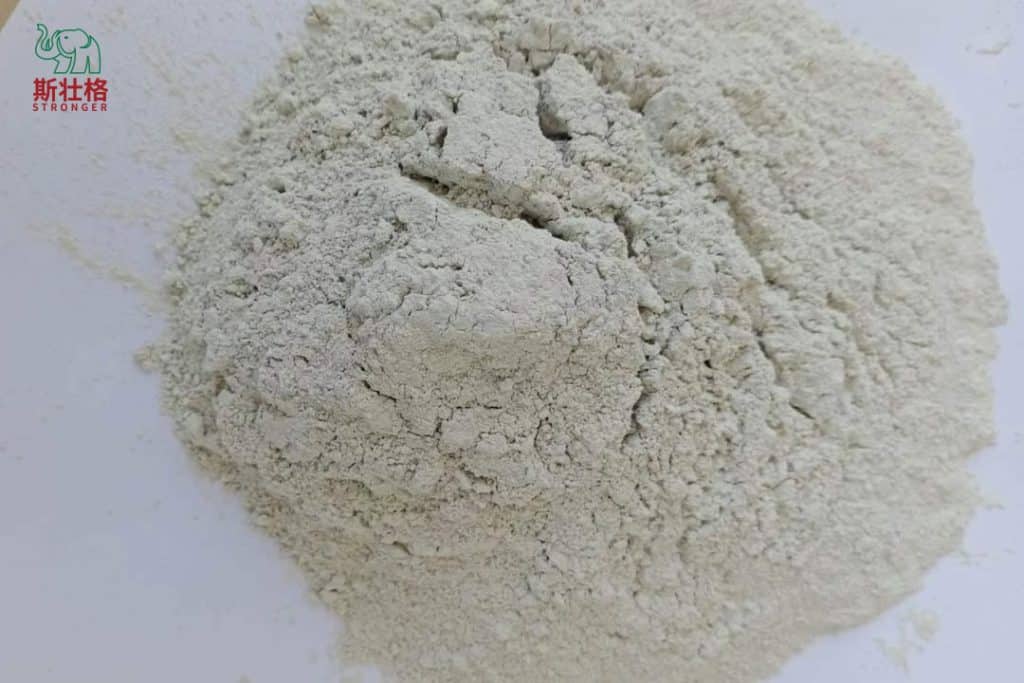

| Status | Powder | Powder |

| Decolorization rate(%)≥ | / | 70.00 |

| DOBI(%)≥ | / | 81.40 |

| Surface Area,m²/g | ≥130 | 180 |

| Free Acid(H₂SO₄),% | ≤0.3 | 0.08 |

| Free Moisture | ≤12 | 7.6 |

| Particle Size (Through 0.075mm mesh),% | ≥90 | 91 |

| Filtration rate | Passed | Passed |

| Bulk Density(g/mL) | 0.55±0.1 | 0.58 |

| PH(50g/L suspension liquid) | 2.2~4.8 | 3.8 |

| Heavy Metal(as pb),mg/kg | ≤40 | <40 |

| As,mg/kg | ≤3 | <3 |

Tips:1.The index rate of DOBI(Deterioration of Bleachabity Index)is based on the comparison of standard samples sent to customers, different customers have different calibration,we take 100% soybean oil decolorization,Yihai Kerry sample as reference.

2.According to customer requirements,indicators and technical solutions can be customized.

Activated Bleaching Clay Benefits For Edible Oil Refinery

An edible oil refinery is a processing plant that converts crude oil into refined oil products meeting quality standards and usage requirements. Below is an overview:

Raw Materials: Primarily derived from various vegetable oil sources (e.g., soybeans, rapeseed, peanuts, sunflower seeds) or animal fats (e.g., tallow, lard), obtained through pressing or solvent extraction.

Products: The main output is refined oils such as Grade 1 soybean oil or Grade 1 rapeseed oil, along with byproducts like phospholipids and vitamin E.

Key Production Processes

Degumming: Removes phospholipids and other gum-soluble impurities to prevent hydrolysis or oxidation during further processing, ensuring oil quality.

Deacidification: Neutralizes or distills free fatty acids to reduce acidity, enhancing oil stability and flavor.

Bleaching: Uses adsorbents (e.g., activated carbon, bleaching clay) to eliminate pigments, off-flavors, and trace metal ions, improving color and appearance.

Deodorization: High-temperature, high-vacuum distillation removes volatile odor compounds, residual solvents, and pigment breakdown products, ensuring a neutral taste and aroma.

Purpose & Significance

Enhances oil quality and shelf life, making it suitable for diverse applications like food processing and cooking.Eliminates harmful contaminants (e.g., aflatoxins, pesticide residues) to ensure consumer safety.

Promotes comprehensive utilization of oils, boosting economic efficiency and resource sustainability in the industry. However using activated clay is most efficient way for oil refinery factory that more economic,safety,environmental,health for people.

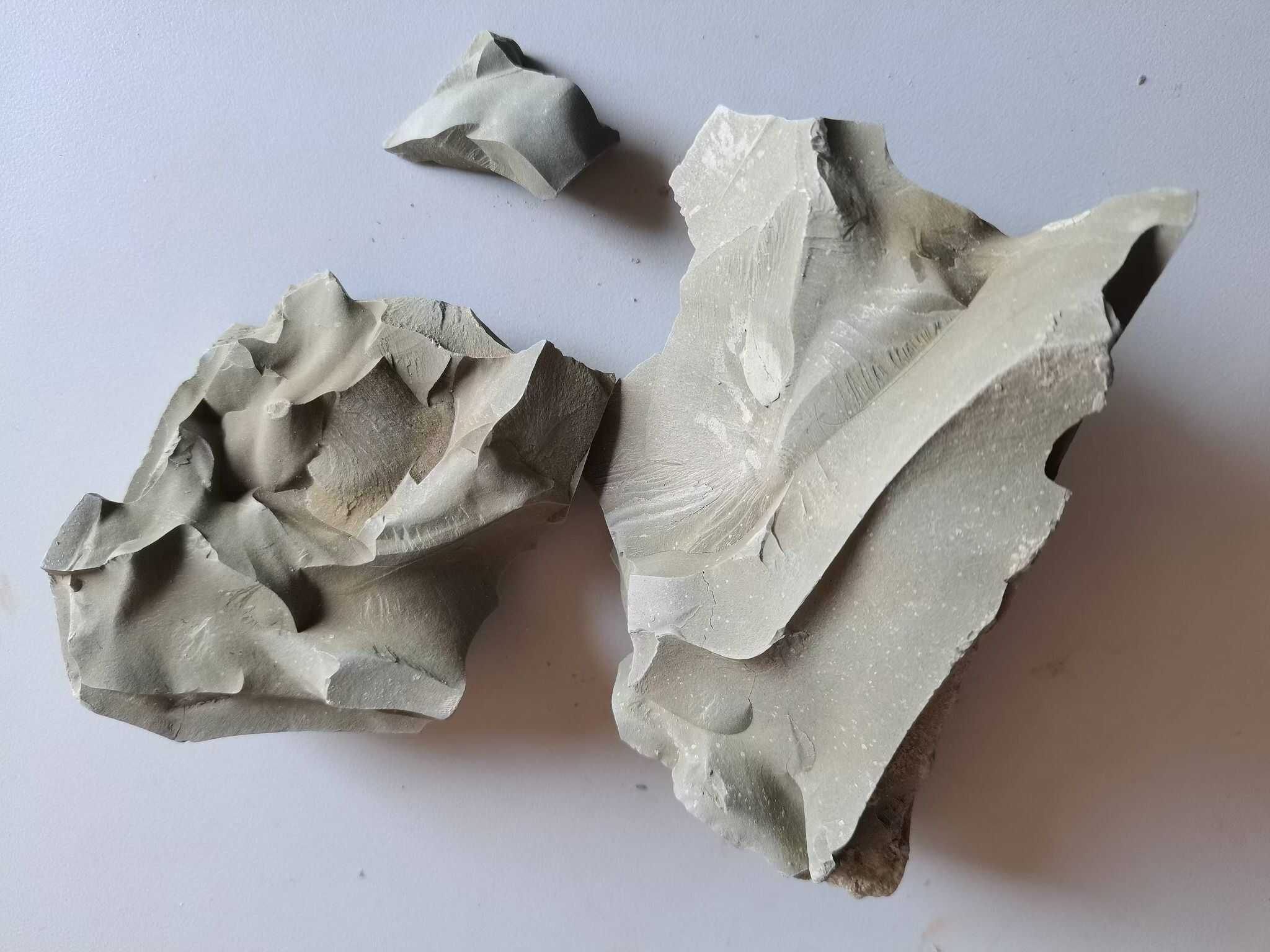

A good way for effective bleaching technology for eatible oil and palm oil purification. A wide range of bentonite activated clay (also known as Bleaching Earth,Bleaching Clay) with various levels of activation. For oil bleaching, color removal and purification of any edible oil including canola, soybean, coconut, palm, fish and sunflower oils, and tallow.

STRONGER activated Bleaching clay we produce demonstrates exceptional stability and purity, characterized by:

1.Superior decolorization rate (industry-leading efficiency)

2.Rapid filtration speed with minimal additive requirement

3.Low residual oil in filter cake & crystal-clear refined oil output

4.Enhanced product stability and process reliability

5.Made from deep natural bentonite that higher purity

High-Performance Activated Bleaching Clay with 85-95% Decolorization Efficiency

STRONGER is a leading manufacturer of activated Bleaching clay (CAS 70131-50-9) in China, specializing in customized adsorbent solutions for global clients in edible oil refining, petrochemicals, pharmaceuticals, and environmental protection industries.

Why Choose STRONGER Activated Bleaching Clay?

Superior Adsorption Performance

Achieves 85-95% decolorization rate for chlorophyll, mycotoxins, and organic impurities in vegetable/animal oils (verified by industrial applications) .

Reduces residual oil rate to <5% through optimized filtration technology, minimizing production costs .

Eco-Friendly Production Process

Utilizes wet process with less acid consumption and higher product efficiency compared to traditional methods, ensuring lower environmental impact .

Certified & Versatile Applications

Complies with food additive standards (GB 2760) for edible oil purification, and effective in wastewater treatment (e.g., radioactive contaminants) .

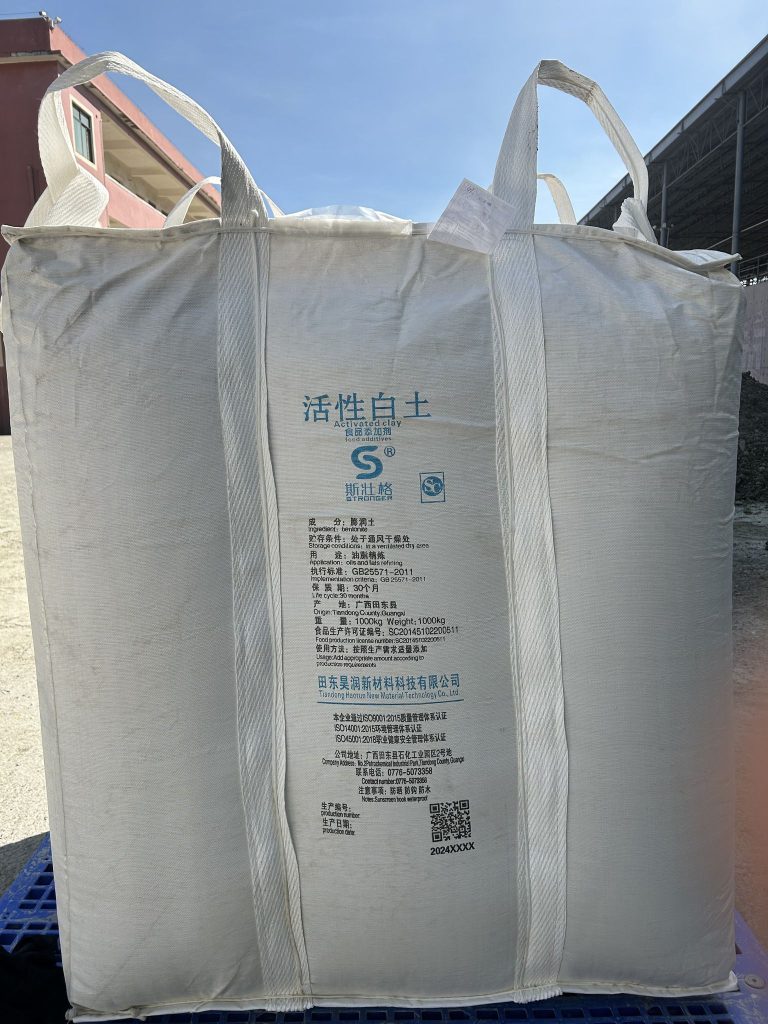

Available in 200-mesh powder or customized granules for catalysts, lubricant synthesis, and pesticide carriers .

Strict Quality Control

12-month shelf life with moisture-proof packaging to maintain activity. heavy metal compliance .

Technical Support & Logistics

Free samples and TDS/MSDS available upon request.

Flexible MOQ: From lab-scale 25g to bulk orders (25kg/drum or 1MT/bag).

Next Step:

Let’s discuss how our activated clay can optimize your production efficiency. We’d be glad to provide a customized quotation based on your application requirements (e.g., oil type, impurity profile).

Attachments:

Product Datasheet

Third-Party Test Report (e.g., TOC, BET surface area ≥180 m²/g)

Activated Clay Factory with trusted, certified, experienced professionals, we focus on innovation, maximize savings, and ensure compliance.

Premium Supplier

Qualified Activated Bleaching Clay Bentonite Factory Premium Supplier

Expert Solution

Activated Bleaching Clay Expert Supplier with qualifications,mining rights, mines

$10/KG

$100/Bag

Popular

$10000/Container

Questions About Activated Bleaching Clay Business

How to Refine Soybean Oil Using Activated Bleaching Earth? (Activated Clay)?

Soybean Oil Refining Process

The use of activated bleaching earth is a critical decolorization step in edible oil refining. It primarily removes pigments (such as chlorophyll, carotenoids), residual trace soaps, phospholipids, metal ions, oxidation products, and other colloidal impurities and off-flavors from the oil.

Below is the standard operating procedure and key considerations for using activated bleaching earth to refine soybean oil:

I. Refining Process (Decolorization Step)

1. Pre-treatment of Crude Oil:

Filtration: Crude soybean oil must first undergo preliminary filtration (e.g., plate-and-frame filter, bag filter) to remove large mechanical impurities (like soybean meal fragments).

Dehydration: If the crude oil has high moisture content (typically required to be below 0.2%), dehydration (e.g., vacuum drying) is necessary, as moisture significantly impairs the adsorption efficiency of the clay.

Degumming & Neutralization: Prior to decolorization, the crude oil usually undergoes degumming (removing phospholipids and other colloids) and neutralization (alkali refining, removing free fatty acids – FFA). These steps remove significant impurities, reducing the load on decolorization and improving clay efficiency. Decolorization typically occurs after neutralization and before deodorization.

2. Preheating the Oil:

Pump the pre-treated soybean oil into a decolorization vessel (typically a vacuum vessel with agitation and heating/cooling jackets).

Under vacuum (typically 50-100 mbar absolute pressure), heat the oil to the required decolorization temperature. The typical temperature range is 90°C – 110°C (194°F – 230°F). Vacuum helps remove air and trace moisture from the oil.

3. Adding Activated Bleaching Earth:

Close off the vacuum source but maintain agitation.

Slowly and evenly sprinkle the calculated amount of dry activated bleaching earth into the oil through a feed port. Key Points:

Dosage: Clay addition is typically 0.5% – 5% of the oil weight. The exact amount depends on:

The initial color depth (Lovibond/RBD color value) of the crude oil.

The desired color of the finished oil.

The adsorption capacity (activity) of the clay itself.

The impurity content of the oil.

Optimal economical dosage is usually determined through lab-scale trials.

Uniformity: Ensure the clay is evenly dispersed throughout the oil to prevent clumping. Effective agitation is crucial. Some processes premix the clay with a small amount of hot oil to form a slurry before adding it to the main vessel.

4. Decolorization Reaction (Contact):

Maintain vigorous agitation at the set temperature (90-110°C / 194-230°F).

Maintain the reaction (contact) time. Typical contact time is 15 – 30 minutes. Insufficient time leads to incomplete adsorption; excessive time can cause oil darkening (color reversion) or increased oil loss.

Towards the end of the contact period, reapply vacuum (or maintain it throughout) to further remove moisture and air.

5. Cooling:

After the designated contact time, circulate cooling water through the jacket to rapidly cool the oil to approximately 70°C – 80°C (158°F – 176°F). Cooling helps:

Stop the adsorption reaction, preventing over-bleaching or side effects.

Reduce oil viscosity for easier subsequent filtration.

Minimize the risk of oil oxidation at high temperatures.

6. Filtration & Separation:

Pump the mixture of oil and spent clay into filtration equipment (commonly plate-and-frame filter presses or leaf filters).

Filter under appropriate pressure to separate the decolorized oil from the spent clay cake containing the adsorbed impurities.

Key Points:

Filtration temperature should not be too low (generally maintained around 70°C / 158°F) to avoid increased viscosity and difficult filtration.

Filter pressure must be controlled carefully, starting low and gradually increasing, to prevent leaks or filter cloth damage.

The initially cloudy oil (first runnings) is usually recycled back for re-filtration.

After filtration, blow the filter cake with a small amount of steam or compressed air to recover trapped oil (cake blowing), minimizing oil loss (foots loss).

7. Post-Treatment:

The filtered decolorized oil may contain traces of clay fines (< 20 ppm) and usually requires polish filtration (e.g., bag filtration, cartridge filtration) for further removal.

Decolorized oil should proceed promptly to the next processing step (typically deodorization) to prevent oxidation or color reversion due to exposure to air and light.

II. Key Control Points & Considerations

1. Clay Selection:

Choose an activated bleaching earth grade specifically suitable for vegetable oil decolorization, particularly soybean oil. Effectiveness varies significantly between manufacturers and clay activities.

Consider clay moisture content (should be low, may require drying before use), particle size distribution (affects filtration rate and residual fines), and pH value (affects oil stability).

Lab-scale testing of new clay batches is recommended.

2. Moisture Control:

Both oil moisture and clay moisture must be strictly controlled. Excessive moisture is a primary cause of poor decolorization efficiency, increased oil loss, and difficult filtration. The system requires good sealing.

3. Temperature Control:

Temperatures that are too low result in slow adsorption and poor results; temperatures that are too high (>120°C / 248°F) risk oil oxidation, polymerization, reduced clay activity, and off-flavor formation. Precise temperature control is vital.

4. Vacuum Level:

Performing decolorization under vacuum helps remove air (oxygen) and trace moisture, preventing oil oxidation and improving decolorization efficiency and oil stability.

5. Agitation:

Ensure thorough and uniform agitation to maximize clay-oil contact and prevent clay sedimentation/clumping. However, avoid excessive agitation that introduces too much air.

6. Contact Time:

Contact time must be optimal. Excessive time increases oil loss and color reversion risk. Determine the best time through experimentation.

7. Filtration Efficiency:

Filtration is critical for production efficiency and oil loss minimization. Select appropriate filter cloths/paper, control filtration temperature and pressure, and clean filter cakes promptly. Incomplete filtration leads to hazy oil (clay residue), affecting downstream deodorization and final product quality.

8. Safety:

Activated bleaching earth is a fine powder. Observe dust control precautions (respirators, ventilation, prevention of dust explosions) during handling to avoid inhalation.

Take precautions against burns during high-temperature operations.

9. Spent Clay Disposal:

Spent clay cake contains approximately 20%-40% entrained oil (a source of oil loss) and adsorbed impurities. It is typically handled as waste, requiring consideration of environmental regulations (e.g., disposal by licensed contractors, or exploration of recycling/recovery methods).

III. Role of Activated Bleaching Earth in Decolorization

Primary Role: Adsorb pigments (decolorization), improving oil color and appearance.

Secondary Roles:

Adsorb trace soaps and metal ions (e.g., iron, copper).

Adsorb phospholipid breakdown products and residual phospholipids.

Adsorb oxidation products (peroxides, aldehydes, ketones).

Adsorb some off-flavor compounds.

Create better conditions for the subsequent deodorization step.

Summary:

Refining soybean oil using activated bleaching earth is a precise physical adsorption process centered on decolorization. Its effectiveness and efficiency depend on numerous factors: clay quality, degree of oil pre-treatment, operating conditions (temperature, time, vacuum, agitation), and filtration performance. Strict process control and parameter optimization are essential for producing decolorized soybean oil with a light color and stable quality. Following decolorization, the oil typically undergoes deodorization to remove volatile odor compounds before becoming a finished refined oil. 😊

How is STRONGER Activated Clay Excellent Decolorization Rate?

1. Higher decolorization ability. The activated clay has a stronger decolorization ability, the decolorization ability of the activated clay is mainly dependent on the adsorption capacity of the pore size for decolorization, the reaction to the index parameters can be seen as higher than the surface area, the activated clay can be up to 280 ㎡/g specific surface area, with a strong adsorption capacity;

How is STRONGER Activated Clay Filtration Speed?

Fast filtering speed. The filter speed of activated clay is lower than that of a similar activated clay, and the filter speed is faster under the same particle size. After comparison, the filter time of 100ml oil under pressure filtration is 30 seconds to more than one minute faster than that of similar competing products.

How is STRONGER Activated Clay Oil Absorption Rate?

Lower residual oil rate after use. Because of the outstanding decolorization ability activated clay, it can reduce the amount of use, and the natural adsorption of less oil can be taken away when the amount of use is reduced.

Do you offer OEM & ODM service for Activated Clay?

Yes, We are fully support for Activated Clay OEM & ODM Service with our stronger engineer team, meet for your wants and needs. STRONGER is An Activated Bleaching Earth supplier with integrated qualifications, mining rights, mines, production facilities and research institutions.

Need more support for about Activated Clay & Bentonite