| Index name | National Standard | STRONGER 223C |

|---|---|---|

| Colour | White/Gray/Light pink | White |

| Status | Powder | Powder |

| Decolorization rate(%)≥ | / | 76.37 |

| DOBI(%)≥ | / | 88.37 |

| Surface Area,m²/g | ≥130 | 180 |

| Free Acid(H₂SO₄),% | ≤0.3 | 0.08 |

| Free Moisture | ≤12 | 7.6 |

| Particle Size (Through 0.075mm mesh),% | ≥90 | 91 |

| Filtration rate | Passed | Passed |

| Bulk Density(g/mL) | 0.55±0.1 | 0.58 |

| PH(50g/L suspension liquid) | 2.2~4.8 | 3.8 |

| Heavy Metal(as pb),mg/kg | ≤40 | <40 |

| As,mg/kg | ≤3 | <3 |

Tips:1.The index rate of DOBI(Deterioration of Bleachabity Index)is based on the comparison of standard samples sent to customers, different customers have different calibration,we take 100% soybean oil decolorization,Yihai Kerry sample as reference.

2.According to customer requirements,indicators and technical solutions can be customized.

Activated Bleaching Clay Benefits For Edible Oil Refinery

An edible oil refinery is a processing plant that converts crude oil into refined oil products meeting quality standards and usage requirements. Below is an overview:

Raw Materials: Primarily derived from various vegetable oil sources (e.g., soybeans, rapeseed, peanuts, sunflower seeds) or animal fats (e.g., tallow, lard), obtained through pressing or solvent extraction.

Products: The main output is refined oils such as Grade 1 soybean oil or Grade 1 rapeseed oil, along with byproducts like phospholipids and vitamin E.

Key Production Processes

Degumming: Removes phospholipids and other gum-soluble impurities to prevent hydrolysis or oxidation during further processing, ensuring oil quality.

Deacidification: Neutralizes or distills free fatty acids to reduce acidity, enhancing oil stability and flavor.

Bleaching: Uses adsorbents (e.g., activated carbon, bleaching clay) to eliminate pigments, off-flavors, and trace metal ions, improving color and appearance.

Deodorization: High-temperature, high-vacuum distillation removes volatile odor compounds, residual solvents, and pigment breakdown products, ensuring a neutral taste and aroma.

Purpose & Significance

Enhances oil quality and shelf life, making it suitable for diverse applications like food processing and cooking.Eliminates harmful contaminants (e.g., aflatoxins, pesticide residues) to ensure consumer safety.

Promotes comprehensive utilization of oils, boosting economic efficiency and resource sustainability in the industry. However using activated clay is most efficient way for oil refinery factory that more economic,safety,environmental,health for people.

A good way for effective bleaching technology for eatible oil and palm oil purification. A wide range of bentonite activated clay (also known as Bleaching Earth,Bleaching Clay) with various levels of activation. For oil bleaching, color removal and purification of any edible oil including canola, soybean, coconut, palm, fish and sunflower oils, and tallow.

STRONGER activated Bleaching clay we produce demonstrates exceptional stability and purity, characterized by:

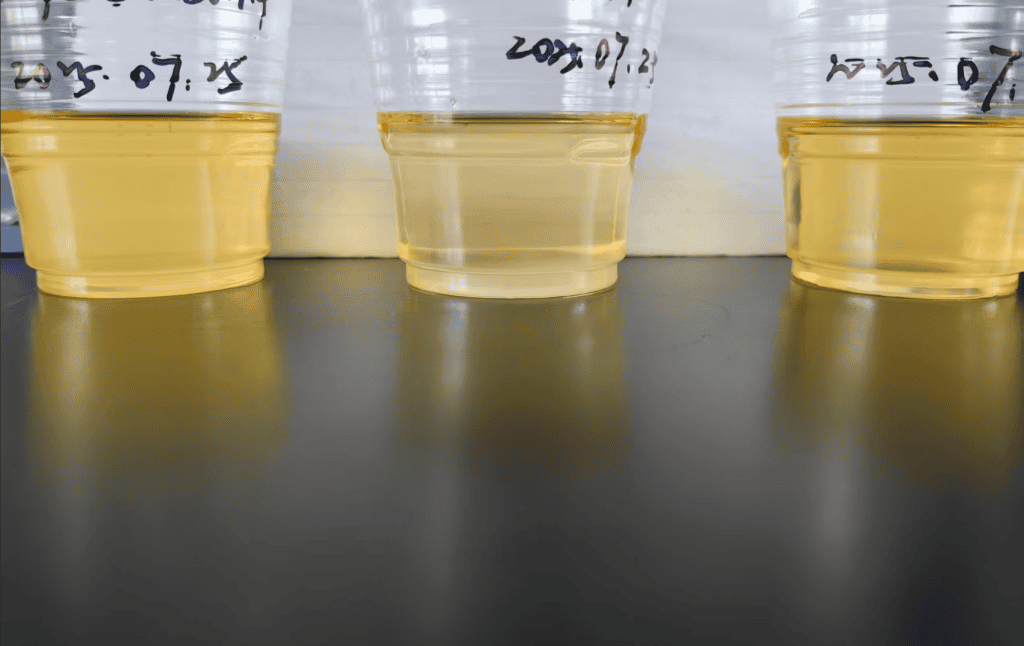

1.Superior decolorization rate (industry-leading efficiency)

2.Rapid filtration speed with minimal additive requirement

3.Low residual oil in filter cake & crystal-clear refined oil output

4.Enhanced product stability and process reliability

5.Made from deep natural bentonite that higher purity

High-Performance Activated Bleaching Clay with 85-95% Decolorization Efficiency

STRONGER is a leading manufacturer of activated Bleaching clay (CAS 70131-50-9) in China, specializing in customized adsorbent solutions for global clients in edible oil refining, petrochemicals, pharmaceuticals, and environmental protection industries.

Why Choose STRONGER Activated Bleaching Clay?

Superior Adsorption Performance

Achieves 85-95% decolorization rate for chlorophyll, mycotoxins, and organic impurities in vegetable/animal oils (verified by industrial applications) .

Reduces residual oil rate to <5% through optimized filtration technology, minimizing production costs .

Eco-Friendly Production Process

Utilizes wet process with less acid consumption and higher product efficiency compared to traditional methods, ensuring lower environmental impact .

Certified & Versatile Applications

Complies with food additive standards (GB 2760) for edible oil purification, and effective in wastewater treatment (e.g., radioactive contaminants) .

Available in 200-mesh powder or customized granules for catalysts, lubricant synthesis, and pesticide carriers .

Strict Quality Control

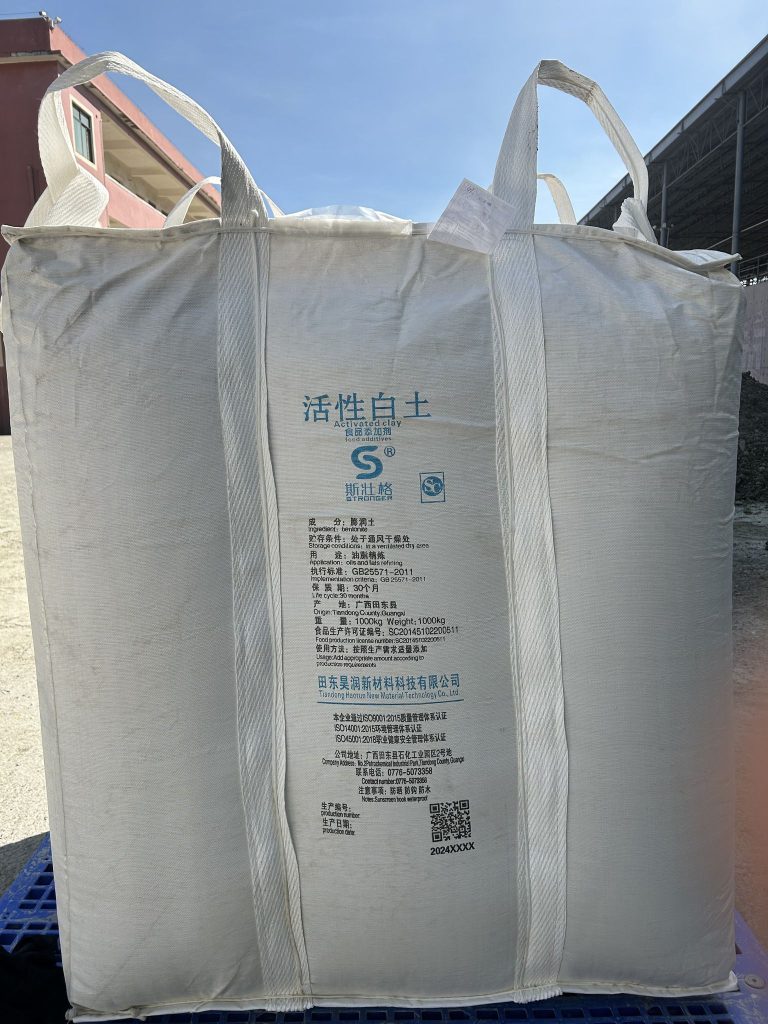

12-month shelf life with moisture-proof packaging to maintain activity. heavy metal compliance .

Technical Support & Logistics

Free samples and TDS/MSDS available upon request.

Flexible MOQ: From lab-scale 25g to bulk orders (25kg/drum or 1MT/bag).

Next Step:

Let’s discuss how our activated Bleaching clay can optimize your production efficiency. We’d be glad to provide a customized quotation based on your application requirements (e.g., oil type, impurity profile).

Attachments:

Product Datasheet

Third-Party Test Report (e.g., TOC, BET surface area ≥180 m²/g)

Activated Clay Factory with trusted, certified, experienced professionals, we focus on innovation, maximize savings, and ensure compliance.

Premium Supplier

Qualified Activated Bleaching Clay Bentonite Factory Premium Supplier

Expert Solution

Activated Bleaching Clay Expert Supplier with qualifications,mining rights, mines

$10/KG

$100/Bag

Popular

$10000/Container

Questions About Activated Bleaching Clay Business

How To Refine Coconut Oil Using Activated Bleaching Earth (Activated Clay)?

Activated bleaching earth refining process for coconut oil

addressing its low melting point, oxidation sensitivity, and phenolic compound preservation:

I. Key Challenges in Coconut Oil Refining

Property Refining Difficulty Risk

High Lauric Acid Hydrolysis at high temperatures FFA surge, flavor degradation

Natural Antioxidants Polyphenol loss from bleaching Reduced oxidative stability

Low MP (24°C/75°F) Filtration clogging Lower refining yield

II. Optimized Bleaching Process

- Critical Pre-treatment

Degumming & Dehydration

Add 0.1% citric acid solution (dissolved at 50°C/122°F), centrifuge to remove gums (phospholipids ≤10 ppm).

Vacuum dehydration (80°C/176°F at 50 mbar) to moisture ≤0.05%.

Pre-deacidification (Physical Method)

Short-path distillation (180°C/356°F, 0.5 mbar) reduces FFA to ≤0.3%.

- Clay Selection & Blending

Component Function Dosage Specifications

Neutral bentonite Adsorbs polar pigments 1.0~1.5% pH 6.5~7.0, pore size >4 nm

Activated carbon Removes heavy metals/3-MCPD esters 0.2~0.5% Iodine value ≥900 mg/g

Silica gel Protects tannins & phenols 0.1% Surface area ≥700 m²/g

Note: Acid-activated clays prohibited (prevent fatty acid hydrolysis catalysis).

- Low-Temperature Adsorption

Temperature: 70±2°C (158±4°F) (critical: >75°C/167°F accelerates lauric acid hydrolysis).

Vacuum: ≤40 mbar (O₂ <0.03%). Contact time: 20 min (polyphenol loss >15% per extra 10 min).

Agitation: Paddle-type low-speed mixing (100–150 rpm).

- Anti-Solidification Filtration

Heated Filtration System:

Jacketed leaf filter (maintain 65–70°C/149–158°F).

Pre-coat with diatomaceous earth (1.0 kg/m² to prevent clay penetration).

Oil Recovery:

Countercurrent washing with hot coconut oil (75°C/167°F) → Residual oil ≤18%.

Cake residual oil: Soxhlet extraction ≤12%.

III. Core Component Preservation

1. Polyphenol Retention

Add 0.01% rosmarinic acid (synchronized with clay addition to reduce polyphenol adsorption).

Target: ≥80% total polyphenol retention (Folin-Ciocalteu assay).

2. Oxidative Stability Control

Immediate post-bleaching cooling to <30°C (86°F).

Nitrogen storage (dissolved O₂ ≤1 ppm).

3. Fatty Acid Profile Protection

Max. process temperature ≤180°C (356°F) (prevent MCFA isomerization).

Trans-fatty acids: ≤0.5% (AOCS Cd 14d-99).

IV. Process Parameters & Testing Standards

Stage Temperature Time Vacuum Key Metrics

Degumming/Dehydration 80°C (176°F) 30 min 50 mbar Phospholipids ≤10 ppm

Physical Deacidification 180°C (356°F) 40 min 0.5 mbar FFA ≤0.3%

Bleaching 70±2°C (158±4°F) 20 min ≤40 mbar Lovibond Y≤15/R≤1.5

Filtration 65–70°C (149–158°F) ≤40 min – Clay residue ≤5 ppm

Final Product Testing:

Peroxide value: ≤1.0 meq/kg (ISO 3960).

Phytosterol retention: ≥90% (GC-FID).

V. Spent Clay Valorization

1. Polyphenol Recovery

Ethanol-water (70:30) extraction → Coconut polyphenol concentrate (cosmetic ingredient).

2. Energy Utilization

Pelletized with coconut shells → Fuel rods (calorific value ≥4,000 kcal/kg).

3. Eco-treatment

Biodegradation: Candida tropicalis fermentation (COD removal ≥85%).

Process Advantages

Yield increase: Total refining yield ≥88% (vs. ≤82% conventional).

Nutrient retention: Vitamin E >95%, total phenols >150 mg GAE/kg.

Safety: Full-process N₂ blanketing (dust <10 g/m³).

Applicability: Suitable for virgin (VCO) and industrial coconut oil (crude color Lovibond Y≤50/R≤8.0).

Technical Notes:

Industry-standard terminology (e.g., “short-path distillation,” “countercurrent washing”).

Dual units (°C/°F) and international test methods included.

Critical parameters explicitly defined for reproducibility.

How is STRONGER Activated Clay Excellent Decolorization Rate?

1. Higher decolorization ability. The activated clay has a stronger decolorization ability, the decolorization ability of the activated clay is mainly dependent on the adsorption capacity of the pore size for decolorization, the reaction to the index parameters can be seen as higher than the surface area, the activated clay can be up to 280 ㎡/g specific surface area, with a strong adsorption capacity;

How is STRONGER Activated Clay Filtration Speed?

Fast filtering speed. The filter speed of activated clay is lower than that of a similar activated clay, and the filter speed is faster under the same particle size. After comparison, the filter time of 100ml oil under pressure filtration is 30 seconds to more than one minute faster than that of similar competing products.

How is STRONGER Activated Clay Oil Absorption Rate?

Lower residual oil rate after use. Because of the outstanding decolorization ability activated clay, it can reduce the amount of use, and the natural adsorption of less oil can be taken away when the amount of use is reduced.

Do you offer OEM & ODM service for Activated Clay?

Yes, We are fully support for Activated Clay OEM & ODM Service with our stronger engineer team, meet for your wants and needs. STRONGER is An Activated Bleaching Earth supplier with integrated qualifications, mining rights, mines, production facilities and research institutions.

Need more support for about Activated Clay & Bentonite